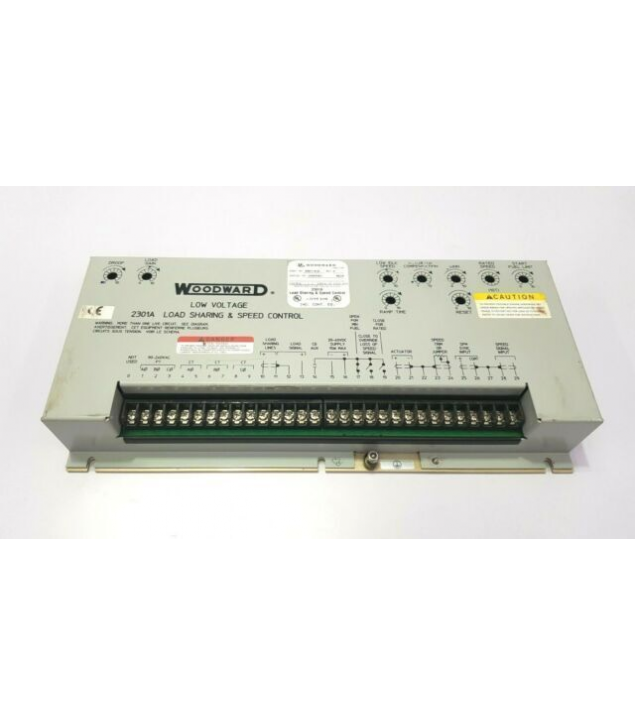

Woodward 9907-018 Control Module

Industrial Automation Control System

Overview

The Woodward 9907-018 is a high-performance control module designed for use in industrial automation and process control systems. As part of Woodward's extensive portfolio of industrial control products, this module provides reliable and precise control capabilities for a wide range of industrial applications.

Engineered to meet the rigorous demands of industrial environments, the 9907-018 offers advanced functionality, flexible configuration options, and seamless integration with existing control systems. Its robust design ensures reliable operation even in harsh operating conditions.

Specifications

Electrical Specifications

- Power Supply: 24 VDC ±15%

- Power Consumption: 10W maximum

- Input Voltage Range: 20-30 VDC

- Isolation: Galvanic isolation between channels

- Fuse Rating: 1A slow blow

Input/Output Specifications

- Analog Inputs: 8 channels, 4-20 mA, 0-10 VDC

- Discrete Inputs: 16 channels, 24 VDC

- Relay Outputs: 6 channels, Form C, 5A @ 250 VAC

- Digital Outputs: 8 channels, open collector

- Communication Ports: 1 x Ethernet, 2 x RS-485

Environmental Specifications

- Operating Temperature: -30°C to +70°C

- Storage Temperature: -40°C to +85°C

- Humidity: 5% to 95% non-condensing

- Vibration: 10-2000 Hz, 10 g peak

- Shock: 50 g, 11 ms duration

Physical Specifications

- Dimensions: 120 x 80 x 180 mm

- Weight: 0.8 kg (approx.)

- Mounting: DIN rail or panel mount

- Enclosure: Powder-coated aluminum

- Ingress Protection: IP20

Features

Advanced Control Algorithms

Incorporates sophisticated control algorithms for precise regulation of industrial processes. Supports PID control, cascade control, and custom control strategies to meet specific application requirements.

High-Speed Processing

Equipped with a powerful microprocessor for fast response times and high-speed signal processing. Enables real-time control and monitoring of critical industrial processes.

Flexible I/O Configuration

Configurable input/output channels allow adaptation to various application requirements. Supports multiple sensor types and signal formats for comprehensive process monitoring and control.

Robust Communication

Multiple communication interfaces including Ethernet and serial ports for seamless integration with plant control systems. Supports industry-standard protocols for easy system integration and data exchange.

Data Logging & Trending

Built-in data logging capabilities for recording process variables, events, and alarms. Supports trend analysis and historical data retrieval for process optimization and troubleshooting.

Diagnostic Capabilities

Advanced self-diagnostic features for monitoring module health and detecting system faults. Provides detailed diagnostic information for quick troubleshooting and maintenance.

Applications

Industrial Process Control

Ideal for controlling and monitoring industrial processes in chemical, petrochemical, and manufacturing industries. Provides precise control of temperature, pressure, flow, and other process variables.

Power Generation

Suitable for power plant automation and control systems. Used in boiler control, turbine monitoring, and electrical system management for efficient power generation.

HVAC Systems

Used in heating, ventilation, and air conditioning systems for commercial and industrial buildings. Provides temperature control, humidity management, and energy optimization.

Water & Wastewater Treatment

Applicable to water treatment plants for process control, monitoring, and automation. Ensures efficient operation of treatment processes and compliance with environmental regulations.

Food & Beverage Processing

Suitable for food and beverage processing applications requiring precise temperature control, flow regulation, and process monitoring. Meets industry standards for hygiene and safety.

Pharmaceutical Manufacturing

Used in pharmaceutical manufacturing processes requiring precise control and documentation. Supports validation requirements and compliance with regulatory standards.

Technical Details

Communication Protocols

- Ethernet: Modbus TCP/IP, Ethernet/IP

- Serial: Modbus RTU, ASCII

- Fieldbus: Profibus DP, DeviceNet

- OPC UA: For secure data exchange

Programming & Configuration

- Software: Woodward ToolKit

- Programming Languages: FBD, LD, ST

- Configuration Storage: Flash memory

- Security: Password protection

Memory & Processing

- Processor: 32-bit RISC processor

- Program Memory: 8 MB Flash

- Data Memory: 4 MB RAM

- Execution Speed: 500 instructions per millisecond

Safety & Certification

- Safety Certification: IEC 61508 SIL 2

- EMC Compliance: IEC 61000-6-2, IEC 61000-6-4

- Hazardous Area: ATEX, IECEx (optional)

- Quality Standard: ISO 9001

Expansion Options

- I/O Expansion: Up to 4 expansion modules

- Communication Cards: Optional fieldbus interface cards

- Redundancy Modules: Hot standby configuration support

- HMI Interface: Optional local operator interface

Response Time

- Analog Input: 8 ms typical

- Discrete Input: 3 ms typical

- Relay Output: 12 ms typical

- Control Loop Update: 25 ms minimum

Additional Information

Maintenance & Support

The Woodward 9907-018 module is designed for minimal maintenance requirements. Regular maintenance includes periodic inspection of connections, cleaning of ventilation openings, and verification of calibration. The module comes with a 1-year manufacturer's warranty, and extended warranty options are available.

Woodward provides comprehensive technical support through a global network of service centers and authorized distributors. Factory training programs are available for maintenance personnel, and 24/7 technical support is offered for critical applications. Software updates and firmware upgrades are available to enhance functionality and maintain compatibility with evolving industry standards.

Woodward, Inc.

Industrial Control Solutions

Document Number: 9907-018-DOC

Last Updated: 2025